Naval architecture applications

The naval architecture and design industry has great challenges during the construction of its products. That’s because designing a yacht is as difficult as it seems. Through additive manufacturing technologies it is possible to create replicas of the final models, even before their launches.

Carlos Eduardo Mariano is the owner of Atelier Naval and with great skill builds beautiful models for the main shipyards in Brazil. Among them we can mention Intermarine, Azimut Yatch, RioStar, Colunna Yatchs, Zonda Boats, Sedna Yachts, Proboat, Ventura Marine, Catarina Yatch, Rio Maguari Shipyard, Zemar Shipyard, Agus Marine, GT Boats and Carbrasmar.

3D printing offers new applications every day. These technologies have definitely changed the way models are designed and produced on an architectural scale, allowing dimensional precision at the industrial level while perfectly printing highly complex geometries.

UP3D solutions for the shipbuilding industry

UP3D specializes in additive manufacturing solutions. It was here that Mariano found the equipment and materials he needed to masterfully produce his projects. This model architect now uses Raise 3D and Tiertime printers in his creations.

Before incorporating these technologies, Mariano used conventional CNC machining processes to create his projects, in an arduous and complicated job. Although traditional manufacturing methods are still great for mass production, Additive Manufacturing is far superior and economical for creating customizable objects as in the case of Atelier Naval.

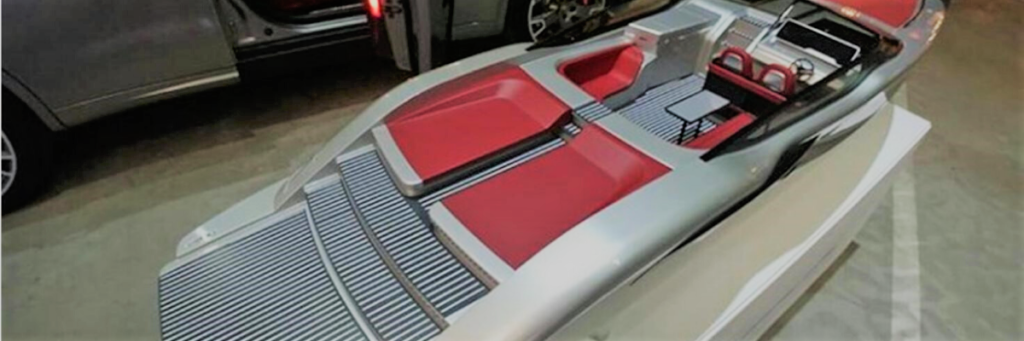

Naval model on an architectural scale

In the case of Mariano, the creation of the models follows the following steps: after creating a CAD file using 3D design software, he loaded the file into the patented Raise 3D slicing software, IdeaMaker, to establish the print settings and determine how to assemble all the pieces. Then, he creates all the individual pieces, hull and structure, from the PLA. The printing of the models has an incomparable resolution, but the beauty of the process is due to the finishing and painting obtained by the hands of the master Mariano.

Results obtained

The use of Raise 3D and Tiertime printers enabled Mariano to dedicate himself to what really matters: his passion for work that turns it into a lucrative business focused on the shipping industry.

Learn more

www.up3d.com.br